Troubleshooting Common Issues in Leather Embossing

Leather embossing is a cherished craft that allows artisans to create intricate designs on leather goods. However, like any creative process, it comes with its set of challenges. Troubleshooting common issues in leather embossing is crucial for achieving impeccable results that reflect your expertise and dedication. In this article, we will delve into 25 key aspects of troubleshooting, providing you with valuable insights and practical solutions to enhance your leather embossing skills.

Troubleshooting Common Issues in Leather Embossing

Leather embossing is a delicate art, and even the slightest issue can mar your masterpiece. Let's explore some common problems faced by embossing enthusiasts and how to overcome them:

Uneven Pressure

Achieving consistent pressure is essential in leather embossing. Uneven pressure can result in incomplete or distorted designs. To resolve this, ensure your embossing machine or tools are well-calibrated and exert uniform pressure throughout the process.

Incorrect Temperature

Temperature plays a pivotal role in embossing. If it's too high, it can scorch the leather; if it's too low, the design won't imprint correctly. Use a thermometer to monitor the temperature and adjust accordingly for optimal results.

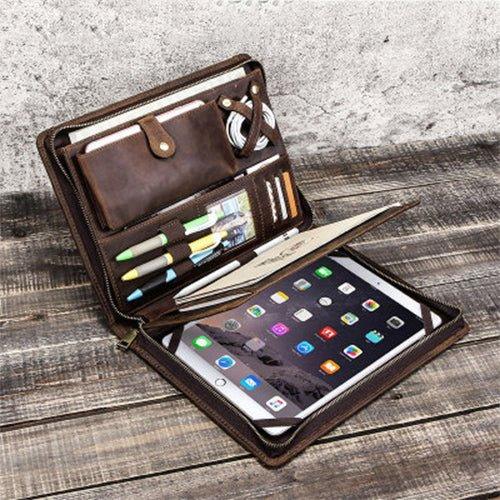

Leather Quality

The quality of leather used greatly affects the embossing outcome. Ensure you're working with high-quality, tanned leather that is suitable for embossing. Subpar leather can lead to unsatisfactory results.

Inadequate Dwell Time

Dwell time refers to the duration the embossing die remains in contact with the leather. Too short a dwell time may result in a faint impression, while too long can damage the leather. Experiment and find the right dwell time for your specific project.

Choosing the Right Die

Selecting the appropriate embossing die is crucial. The design, size, and depth of the die should align with your project's requirements. Using the wrong die can lead to design distortion and disappointment.

Insufficient Moisture

Leather requires moisture to become pliable for embossing. Ensure the leather is adequately moistened before the embossing process. A spray bottle can be handy for evenly distributing moisture.

Inadequate Preparation

Skipping essential prep steps, such as cleaning and smoothing the leather surface, can result in imperfections. Take the time to prepare the leather properly before embossing.

Handling Bubbles

Air bubbles trapped between the leather and the embossing die can create voids in the design. Use a roller or your hands to carefully press out any air bubbles during embossing.

Proper Alignment

Aligning the leather and die accurately is crucial for a clean design. Invest in alignment tools or guides to ensure precise placement before embossing.

Overworking the Leather

Excessive embossing attempts in the same area can damage the leather and lead to over-embossing. Practice restraint and avoid overworking specific sections.

Storing Dies Properly

Storing your embossing dies improperly can lead to damage or deformation. Store them in a cool, dry place and protect them from dust and moisture.

Using Adequate Pressure

Applying too much pressure can cause the design to bleed, while insufficient pressure won't yield clear results. Find the right balance by practicing on scrap leather.

Cleaning the Die

Residue on the embossing die can transfer onto the leather, affecting the design's clarity. Clean the die regularly to maintain crisp impressions.

Troubleshooting FAQ

Q: How can I prevent scorching the leather during embossing?

A: To avoid scorching, monitor and control the temperature closely. Use a temperature-regulated embossing machine or tool.

Q: What should I do if the leather tears during embossing?

A: Tears can occur due to excessive pressure. Reduce the pressure or use a thicker leather to prevent tearing.

Q: Can I emboss suede leather?

A: Suede can be embossed, but it requires special care due to its delicate nature. Use a lower temperature and lighter pressure.

Q: What's the best way to remove air bubbles?

A: Gently press out air bubbles using a roller or your fingers, starting from the center and moving outward.

Q: How can I fix an unevenly embossed design?

A: An uneven design often results from uneven pressure. Calibrate your embossing equipment and apply even pressure throughout.

Q: Can I emboss leather without a machine?

A: Yes, it's possible to emboss leather by hand, but it requires more effort and precision.

Conclusion

Mastering the art of leather embossing takes time and practice. Troubleshooting common issues in leather embossing is a crucial part of this journey. By addressing these challenges with care and precision, you'll enhance your skills and create stunning leather goods that showcase your expertise and passion.