Industrial Applications of Waxed Canvas

What is Waxed Canvas and What Makes it Useful for Industry?

Waxed canvas is a durable, water-resistant material often used in heavy-duty industrial applications. It is made by applying wax to canvas, a tightly woven cotton fabric. The wax penetrates the fibers of the canvas to make it highly water repellent while still retaining breathability. Waxed canvas is valued for its strength, abrasion resistance, and flexibility, allowing it to be used in many demanding settings. Its ability to withstand moisture, mildew, and mold also makes waxed canvas well-suited for outdoor use. These attributes have led to waxed canvas being utilized across transportation, agriculture, construction, military, and manufacturing settings which require dependable, high-performance materials.

A Look Back at the History and Evolution of Waxed Canvas

The waterproofing properties of wax have been known since ancient times. Early civilizations waterproofed items like rain capes, tents, and ship sails using wax. Waxed canvas itself has origins dating back several centuries, first utilized by Scottish fishermen to create protective covers and gear for their boats. The British Navy then adopted it in the 1800s for uniforms and foul-weather gear, recognizing its hardy nature. As industrialization spread, waxed canvas was increasingly manufactured in mills and tailored for wider practical applications. Over the decades it transitioned from small-batch waxing techniques to more efficient mechanized production. Additional innovations like flexible riders jackets led to the material's use by pioneers, soldiers, and adventurers braving the outdoors. Today waxed canvas is produced globally, benefiting from modern materials and methods while retaining its core rugged, reliable qualities. Its flexibility, durability, and water-resistance continue to serve key functions across many industries.

Step-by-Step: How Waxed Canvas is Made

Waxed canvas starts with tightly woven, medium or heavy weight cotton canvas. Wax is then applied in several steps:

- The dry canvas is dipped into a paraffin-based wax and is passed through rollers to saturate the material.

- Next it goes through high pressure wringers to remove any excess wax. This allows penetration into the fabric weave while preventing oversaturation.

- The waxed canvas is then hung and slowly dried in ovens to cure the wax fully into the cotton fibers. Drying times range from 24-72 hours at low consistent temperatures.

- After drying, the canvas is inspected for quality assurance. Samples are tested to verify water resistance and other properties before being approved.

- Additional wax formulas like beeswax or linseed oil may be used to modify properties like pliability and appearance. The canvas can also be dyed different colors as desired.

- The finished waxed canvas is ready to be cut and stitched into products suitable for heavy industrial use. Rigorous manufacturing standards ensure consistent, high-grade waxed canvas.

Why Waxed Canvas is Ideal for Many Industrial Applications

Water and Moisture Resistance

The wax infusion process makes waxed canvas highly water repellent while still allowing breathability. Liquids bead up and run off its surface while vapor can escape. This makes it perfect for outdoor gear or equipment regularly exposed to rain and dampness.

Tear and Abrasion Resistance

The dense cotton weave combined with wax boosts the material's durability against rips, punctures, and abrasions from rough handling. This makes waxed canvas suitable to withstand demanding daily use and rugged conditions.

Mold, Mildew, and Rot Resistance

Waxed canvas is also treated to resist mold, mildew, and bacterial growth. Its oil and wax coatings block moisture penetration that could cause rot or deterioration, helping it last longer. This property extends its life especially in damp environments.

Customizable Wax Formulas

Wax blends can be modified with beeswax, linseed oil, and other additives to alter waxed canvas properties for specialized uses. Custom waxes provide flexibility to tweak performance as per specific industry requirements.

High Strength-to-Weight Ratio

Waxed canvas has a high strength-to-weight ratio. It is dense and sturdy yet still relatively lightweight compared to other waterproof industrial fabrics like rubber. This makes waxed canvas desirable where strength is needed without adding unnecessary weight.

Major Applications Across Industries

Transportation Industry Relies on Waxed Canvas

Waxed canvas is indispensable in the transport sector where vehicles and equipment face constant exposure to weather, dirt, and rough use while in transit or storage. Key applications include:

- Truck Tarpaulins and Covers: Waxed canvas tarps and covers protect truck cargo from rain, debris, and wind during transport. The material is durable to withstand highway speeds and loading/unloading abrasion.

- Boat Covers and Sails: Being highly water repellent, waxed canvas is ideal for boat deck covers, sails, and other marine gear regularly subjected to moisture. Wax formulas are even customized to suit ocean use.

- Auto and Carriage Covers: Vintage car collectors and museums utilize waxed canvas covers to protect vehicles when in storage or on display. The material resists moisture, dust, and scrapes from install/removal.

- Horse Tack and Stable Gear: Waxed canvas continues to be used for horse saddles, straps, and other equestrian accessories where wet weather and outdoor use resistance is vital.

Agriculture and Farming Applications

Waxed canvas assists farmers and agriculture by protecting equipment and keeping harvests dry:

- Tractor and Heavy Equipment Covers: Waxed canvas tarps and covers shield farm vehicles and machinery from rain, dirt, and corrosion when not in use. The fabric stands up to heavy use cycles.

- Silo Covers and Grain Storage Bags: To keep grains and feed dry, waxed canvas is perfect for covering silos and making storage bags. The wax resists moisture absorption and seepage.

- Animal Equipment: Horse saddles, bridles, reins, etc benefit from waxed canvas pieces. The material withstands animal contact, dirt, rain, and regular cleaning.

Construction and Manufacturing Settings Utilize Waxed Canvas

Builder and factories benefit from the durability of waxed canvas:

- Protective Workwear: Waxed canvas aprons, work gloves, caps, and overalls protect workers from spills, debris, and heavy-duty conditions. Wax makes the fabric shed liquids and easier to clean.

- Dust and Debris Covers: Equipment and vehicles on construction sites get covered in waxed canvas tarps to protect from fine dust ingress when idle. The material is abrasion resistant to endure frequent installs.

- Material Transport: Waxed canvas bags and wraps keep building materials like tools or cement powder dry in transit. The fabric survives loading, unloading, and storage.

The Military Trusts Waxed Canvas Gear to Endure

Waxed canvas is valued for field use across branches of the armed forces:

- Tents and Shelters: Troop sleeping quarters and medic tents made of waxed canvas resist moisture from rain and snow. The material stands up to field use and frequent assembly.

- Supply Bags: Duffel bags, rucksacks, and ammo pouches are often made with waxed canvas to keep supplies protected and dry during transport.

- Camouflage Covers: Waxed canvas tarps and netting treated with camo patterns conceal equipment and positions, rain or shine. The fabric survives grind of field use.

- Vehicle and Artillery Covers: Waxed canvas protects artillery gun barrels, mobile command centers, and vehicles during transport to reduce wear. Durable and waterproof, it is trusted for field use.

Key Factors When Selecting Waxed Canvas for Projects

Choosing waxed canvas involves assessing attributes like:

- Intended Use: Consider exposure to abrasion, dirt, liquids, and other hazards the material must withstand. Select wax type and canvas weight accordingly.

- Frequency of Use: Material intended for daily heavy use needs to be thicker and more durable versus occasional use. Factor in wear and tear.

- Environment: Will the waxed canvas be primarily indoors or outdoors? How much rain, humidity, and UV exposure is expected? Prioritize waterproofness for wet conditions.

- Maintenance: Some applications require easy periodic re-waxing. Lighter wax coats simplify this process.

- Aesthetics: Do you need uniform colors or a distressed vintage look? Wax formulas and dyes offer different visual styles.

- Cost: Thicker canvas and special wax blends are more expensive. Balance performance needs with budget.

By evaluating these aspects, industrial buyers can select the ideal waxed canvas to serve each application reliably for years.

Caring for Your Waxed Canvas Gear

To get the most value from waxed canvas, proper care and maintenance is key:

- Re-wax annually or as needed: Over time, dryness or stains may indicate the need for re-waxing to restore water resistance and appearance. Use sparing, even coats of wax.

- Check for cracks or holes: Periodically inspect for rips, cracks, or holes and patch promptly before they spread. Use wax-based sealants to fix small holes.

- Clean gently: Use a stiff brush and lukewarm water to remove most dirt. Avoid detergents that can strip wax. Let dry fully before storing.

- Proper storage: Allow waxed canvas gear to fully air dry before folding away. Store in a cool, dry place away from direct sunlight when possible.

- Avoid high heat: Excess heat from sources like dryers and radiators can damage wax coatings. Allow to air dry only.

With proper care, quality waxed canvas can serve reliably for over a decade even in demanding industrial use.

What Does the Future Hold for This Versatile Material?

While waxed canvas has a venerable history, it continues to evolve and find new applications:

- Sustainable wax blends: Bio-sourced waxes and non-toxic formulations reduce environmental impact. Natural waxes like beeswax are also being revived.

- Combinations with modern fabrics: Pairing waxed canvas with advanced materials like Kevlar and neoprene augments certain properties like cut or chemical resistance.

- Novel industrial uses: New frontiers like solar panel cleaning, compost containment, and concrete curing utilize waxed canvas in creative ways.

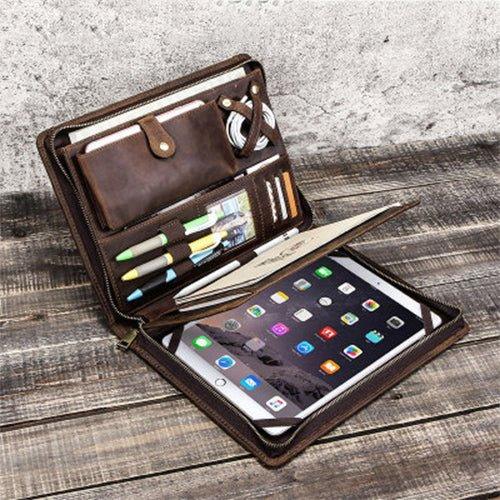

- Fashion and accessories: Waxed canvas sees growing popularity in bags, jackets, and other consumer items due to its good looks and sustainability.

In a future gravitating towards natural, durable materials, waxed canvas is poised for an even greater role blending heritage with innovation across industries.

In Conclusion

With its blend of ruggedness, flexibility, and water repellency, waxed canvas has become a mainstay material keeping major industries running smoothly. It brings vital performance and protection across transportation, agriculture, construction, military, and manufacturing sectors operating in the harshest conditions. While waxed canvas honors its maritime and pioneering roots, it continues to evolve through sustainable wax blends and novel uses as a trusted industrial problem-solver.